John and David Shearer and the Shearer Motor Car, Mannum, South Australia

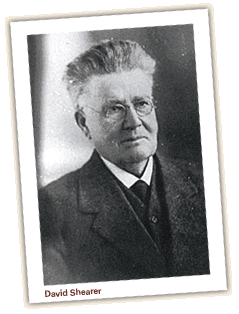

SHEARER, JOHN (1845-1932) and DAVID (1850-1936), agricultural machinery manufacturers and inventors, were two of the five sons of Peter Shearer, stonemason and blacksmith, and his wife Mary, née Kirkness. John was born on 9 September 1845 and David on 7 November 1850 in the Orkney Islands, Scotland. The family migrated to South Australia in 1852, living in Port Adelaide, Robe and, later, Clare where the brothers were educated.

After an apprenticeship with Hanlon & Co., blacksmiths, John started a blacksmith’s business at Mount Torrens. There, on 15 July 1871, he married 15-year-old Mary Jane Watkins. Later he joined J. G. Ramsay & Co., agricultural implement-makers, Mount Barker, and in 1876 started a smithing business at Mannum on the River Murray, repairing paddle-steamers and farmers’ implements and shoeing horses.

At 14 David attended Joseph Cole’s Stanley Grammar School for a year, paying his fees with wages saved from two years as a farm-hand. In 1865-67 he helped his brother William, a blacksmith at Leasingham, then spent two years as an improver at James Ramsay’s Clare branch; later he worked for Adamson & Co., Auburn, at wagon building. After eighteen months in John’s business at Mount Torrens, he was with Strike & Short, wagon builders and blacksmiths, Rice Creek, a firm which he bought in 1874. On 28 February 1883 in Adelaide David married Mary Elizabeth Williams.

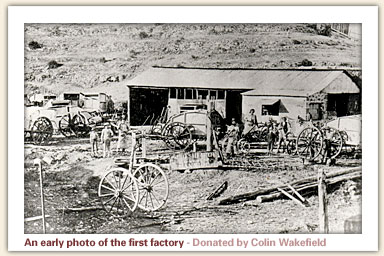

It was in 1877 that John and David Shearer set up their little forge and began making the implements destined to pave the way to riches for Australian farmers. It was the invitation of Mannum farmers that brought the Shearers to Mannum, and the farmers gave them their full support…support that was not misplaced, for the name ‘Shearer’ quickly established itself. Along the Murray as far as a paddle steamer could thresh its picturesque way went the agricultural implements that separated the wealth from the rich Australian soil.

In the early days the surrounding districts of Mannum were densely covered with mallee and pine. Farmers needed tough equipment to clear the land before making it pay. And it was here that the Shearer Brothers stepped in with several new machines, adding Stump Jump Ploughs to the grubbing machines, fixed ploughs, scarifiers and harrows already being produced. The implements were rugged and built for the local conditions; they found a ready market in the district and other parts of South Australia.

Up to this date farmers had the choice of two plough shares, a cast iron share that broke easily, or a forged share that was almost prohibitive in price. Determined to solve this expensive problem for farmers, John and David Shearer went to work, and in 1888 invented a virtually unbreakable wrought steel plough share at one quarter the price of the old forged share. These shares swept Australia in popularity and saved farmers millions in plough-share costs.

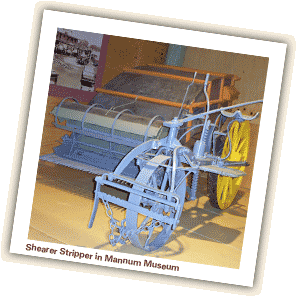

Business had increased enormously by 1895. Shearer strippers were in terrific demand. The only answer was to enlarge the factory still more and install more plant. But as they expanded their business the Shearer brothers made still more improvements, and in 1902 a lighter, stronger stripper with a wider cut was made and enthusiastically received by farmers. Farm wagons too were manufactured at this time.

10 years before Henry Ford in America had built his automobile, David Shearer, at Mannum, had built a steam car with the world’s first differential. The restored car is now on permanent display at the National Motor Museum in Birdwood, South Australia.

| Extract from ‘The Mail’ Saturday 10 July 1926 Australia’s First Motor Car – Mannum Manufacturer’s Invention Well known in South Australia as a manufacturer of farm implements, Mr David Shearer, of Mannum, River Murray, can claim to be Australia’s first inventor of a motor car.

England’s first car, which made its appearance two years after Mr Shearer’s had a speed of 10 to 12 miles an hour, while the South Australian car actually travelled at 15 miles an hour. In 1900, several years after the car had been running in and around Mannum, it was driven to Adelaide and exhibited in the Chamber of Manufactures Exhibition. It careered around the city terraces at 15 miles an hour, by special permission of the Mayor, “but” says Mr Shearer, “the horses were not used to it and much profanity was directed at my head by the drivers of horse drawn vehicles”. After demonstrating to the farmers of his time that the horseless carriage was a possibility, Mr Shearer did not persist in his experiment and turned his attention to the manufacture of harvesters, strippers, harrows and ploughs, thus Australia was probably deprived of the all Australia motor car. |

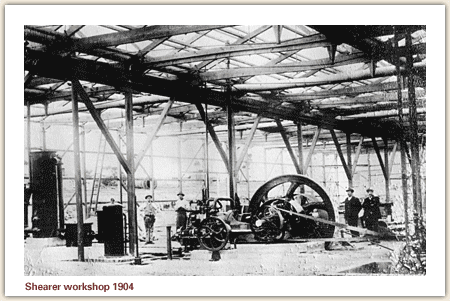

The increase in South Australia’s population, and the difficulties experienced in those days of transporting farm implements from Mannum to Adelaide finally meant forming a branch of the firm at Kilkenny, Adelaide in 1904. Ploughs and other tillage implements were made at the Kilkenny factory, and allowed the Mannum factory to concentrate on strippers, wagons, harrows and plough shares. In this way distribution was simplified, and both factories had more room for new plant, essential in the Shearer Brothers’ Expansion programme.

In 1910 the completion of a large, new factory at Mannum made on the ‘saw-tooth’ roof principle meant more room, more light and greater comfort for the men. It was in 1910 that the brothers, John and David, decided to dissolve partnership. The businesses at both Kilkenny and Mannum were securely under way, and it was decided that David should continue at Mannum, making harvesting equipment, harrows and plough shares, while John, at Kilkenny, make tillage equipment.

Insistent demands from farmers led to David Shearer taking up the manufacture of stripper harvesters. These machines following the specifications of farmers, were made to stand up to rough conditions and proved very successful, particularly to Mallee farmers.

For a while agricultural equipment faded into the background while the factory went flat out making war equipment such as munition wagons, saddle stirrups and hames. It was a war effort that called for full production, so the well equipped factory and the trained workers gave their best for their country.

With the demand of the company’s products still on the increase it was found necessary to make extensive additions to the factory in 1927. The factory, as originally built in 1910, was entirely used for manufacturing component parts, and the new additions were used for assembling and painting.

David Shearer Limited first placed the header harvester on the market in 1927, and it was an immediate success. Popularity was such that this type of machine went on to take the major portion of the factory’s capacity in the early 1950s. It showed once again the wisdom of following the requirements of the man on the land.

When the call for munitions came again, David Shearer Limited had over 300 employees working round the clock to produce vital equipment, over 1 000 000 malleable iron track links for Bren Gun Carriers were made. Drop forgings for the Anti-Tank Gun, spanners, shackles and many other forgings, pressings and castings were also produced. The manufacture of this equipment for government departments during the war led to numerous enquiries to continue the manufacture of contract work for the general industrial trade.

To handle the increased trade in New South Wales, in 1947 a separate company, David Shearer Pty Ltd, was formed and located at 62 Railway Parade, Burwood, near Sydney, to handle the sales and service of the parent company’s products.

In 1950 the extent of enquiries in the United Kingdom and the continent were such that an overseas office had to be established. So David Shearer Limited had yet another address, this time at Aldwych House, London. This London office also bought overseas material for the South Australian plant.

Becoming a public company in 1952 with an authorised capital of $2 000 000, the development of agricultural machinery progressed through various headers.

To facilitate the distribution of spare parts, a depot was opened at 236 Port Road, Alberton, South Australia in 1954. This depot was a combined showroom and spare parts centre. During the rural recession it was closed as a spare parts centre.

In 1968 the first Prince Philip Prize for Australian Design was awarded to David Shearer Limited for the XP88 self-propelled header.

In 1972 David Shearer Limited became the Mannum division of Horwood Bagshaw Limited.

In 1977 the Mannum Division of Horwood Bagshaw Limited employed approximately 380 people which at the time was about 60% of the town’s workforce.

In 1998 Horwood Bagshaw was purchased by Adelaide based Sweeney Investments to become a South Australian privately owned and based company.

Over the next ten years the factory at Mannum was extensively upgraded and continues to operate two divisions; contract engineering and agricultural machinery

![]() Take the Shearer Historic Walk in Mannum | Click here to visit the Mannum Museum

Take the Shearer Historic Walk in Mannum | Click here to visit the Mannum Museum